Filamen ABS Torwell 1.75mm kanggo printer 3D lan pulpen 3D

Fitur Produk

| Merek | Torwell |

| Bahan | QiMei PA747 |

| Diameter | 1.75mm/2.85mm/3.0mm |

| Bobot bersih | 1 Kg/gulungan; 250g/gulungan; 500g/gulungan; 3kg/gulungan; 5kg/gulungan; 10kg/gulungan |

| Bobot kotor | 1.2Kg/gulungan |

| Toleransi | ± 0,03mm |

| Dawane | 1,75mm (1kg) = 410m |

| Lingkungan Panyimpenan | Garing lan berventilasi |

| Setelan Pangatusan | 70˚C sajrone 6 jam |

| Bahan pendukung | Aplikasi nganggo Torwell HIPS, Torwell PVA |

| Persetujuan Sertifikasi | CE, MSDS, Jangkauan, FDA, TUV, SGS |

| Kompatibel karo | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker lan printer 3D FDM liyane |

Werna Liyane

Werna sing kasedhiya:

| Werna dhasar | Putih, Ireng, Abang, Biru, Kuning, Ijo, Alam, |

| Werna liyane | Perak, Abu-abu, Kulit, Emas, Jambon, Ungu, Oranye, Kuning-emas, Kayu, Ijo Natal, Biru galaksi, Biru langit, Transparan |

| Seri fluoresen | Abang Neon, Kuning Neon, Ijo Neon, Biru Neon |

| Seri sing sumunar | Ijo Cahya, Biru Cahya |

| Seri sing ganti warna | Biru ijo nganti kuning ijo, Biru nganti putih, Ungu nganti Jambon, Abu-abu nganti Putih |

| Nampa Werna PMS Pelanggan |

Pameran Model

Paket

Filamen ABS gulungan 1kg nganggo pengering ing kemasan vakum.

Saben spool ing kothak individu (kothak Torwell, kothak Netral, utawa kothak Khusus sing kasedhiya).

8 kothak saben karton (ukuran karton 44x44x19cm).

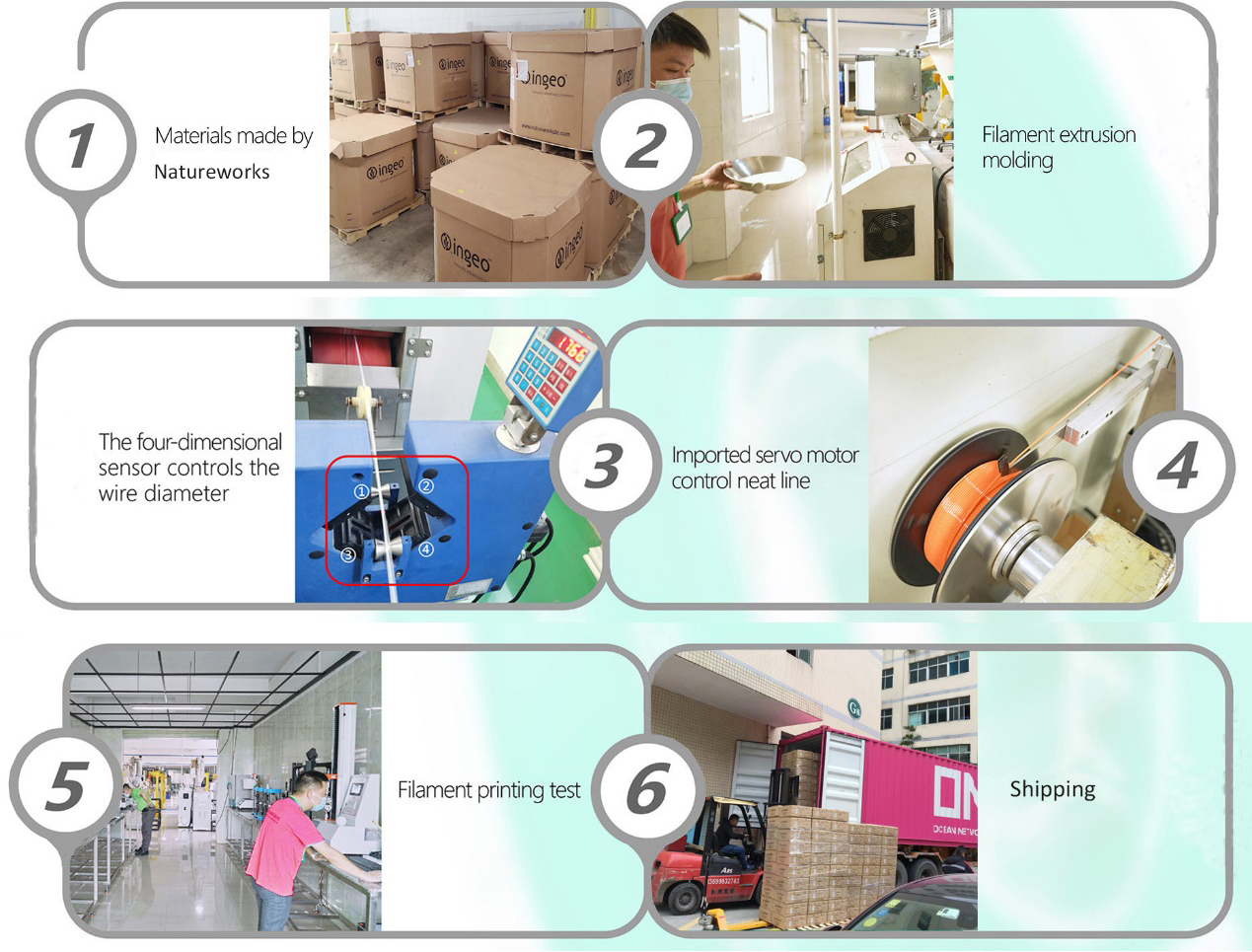

Fasilitas Pabrik

Cathetan Penting

Tulung lebokna filamen liwat bolongan sing wis dipasang supaya ora kusut sawise digunakake. Filamen ABS 1.75 mbutuhake heat-bed lan permukaan cetak sing tepat supaya ora melengkung. Bagean gedhe gampang melengkung ing printer domestik lan ambune nalika dicetak luwih kuwat tinimbang PLA. Nggunakake raft utawa brim utawa nyuda kecepatan kanggo lapisan pertama bisa mbantu nyegah melengkung.

Pitakonan sing Sering Ditakoni

Yèn benang-benangé ora bisa nempel ing amben bangunan, kenapa ya?

1. Priksa setelan suhu sadurunge nyetak, filamen ABS duwe suhu ekstrusi sing luwih dhuwur;

2. Priksa manawa permukaan pelat wis digunakake sajrone wektu sing suwe, disaranake ngganti karo sing anyar kanggo njamin adhesi lapisan pertama sing kuwat;

3. Yen lapisan pertama kurang adhesi, disaranake kanggo ngratake maneh substrat cetak kanggo nyuda jarak antarane nozzle lan pelat permukaan;

4. Yen efeke ora apik, disaranake nyoba nyetak draf sadurunge nyetak.

| Kapadhetan | 1,04 g/cm3 |

| Indeks Aliran Leleh (g/10 menit) | 12(220℃/10kg) |

| Suhu Distorsi Panas | 77℃, 0.45MPa |

| Kekuwatan Tarik | 45 MPa |

| Pemanjangan nalika Pedhot | 42% |

| Kekuwatan Fleksibel | 66.5MPa |

| Modulus Fleksibel | 1190 MPa |

| Kekuatan IZOD | 30kJ/㎡ |

| Kekuwatan | 8/10 |

| Kamungkinan dicithak | 7/10 |

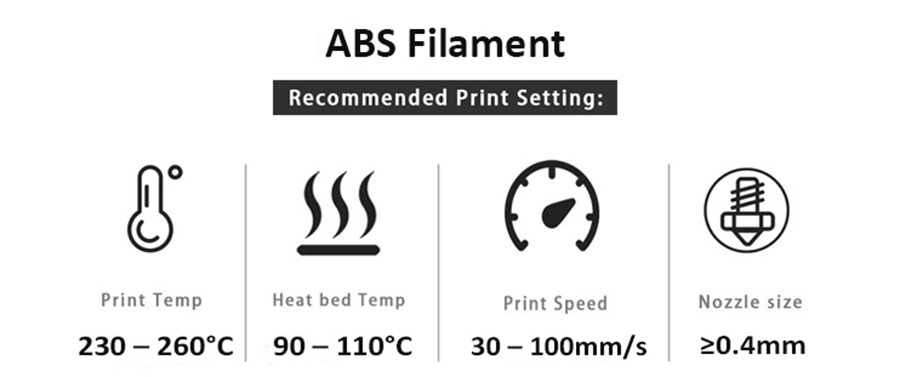

| Suhu Ekstruder (℃) | 230 – 260℃Disaranake 240℃ |

| Suhu amben (℃) | 90 – 110°C |

| Ukuran Nozzle | ≥0.4mm |

| Kacepetan Kipas | RENDAH kanggo kualitas permukaan sing luwih apik / MATI kanggo kekuatan sing luwih apik |

| Kacepetan Nyetak | 30 – 100mm/dtk |

| Amben sing digawe panas | Dibutuhake |

| Permukaan Bangunan sing Disaranake | Kaca nganggo lem, Kertas penutup, Lakban Biru, BuilTak, PEI |